Dry-fit Brick Facades

Brick facades. Without bricklaying.

Dry-fit panels that install in days, not weeks. No bricklayers, no wet trades, no weather delays. A hyper-realistic brick finish your planners and residents will approve.

Dry-fit Brick Facades

Dry-fit panels that install in days, not weeks. No bricklayers, no wet trades, no weather delays. A hyper-realistic brick finish your planners and residents will approve.

As featured on

Zero-Ambitions Podcast

"VundaHaus is changing the game in external wall insulation - faster, smarter, and more effective" - Dan Hyde, Host

The Panel

Patent-pending cementitious panels with a finish that goes all the way through. It's not acrylic. It's not a thin skin. It's the closest thing to real brickwork without laying a single brick.

Actual panel finish - example

A1/A2 rated cementitious materials from front to back. No acrylic anywhere.

One person can pick it up and fix it. No crane hire, no telehandler, no lifting gear.

The finish goes all the way through. A knock or scrape reveals the same material underneath.

Unlike acrylic slip systems, there's no bonded surface layer to peel or separate.

No maintenance, no repainting, no degradation. The last facade you'll ever need.

Brick Matching

You specify the brick you want. We make it. From handmade London stocks to red multis for housing estates, we match local brick types, reproduce premium finishes, and create heritage effects. Every brick in every panel is unique in colour, texture, and geometry.

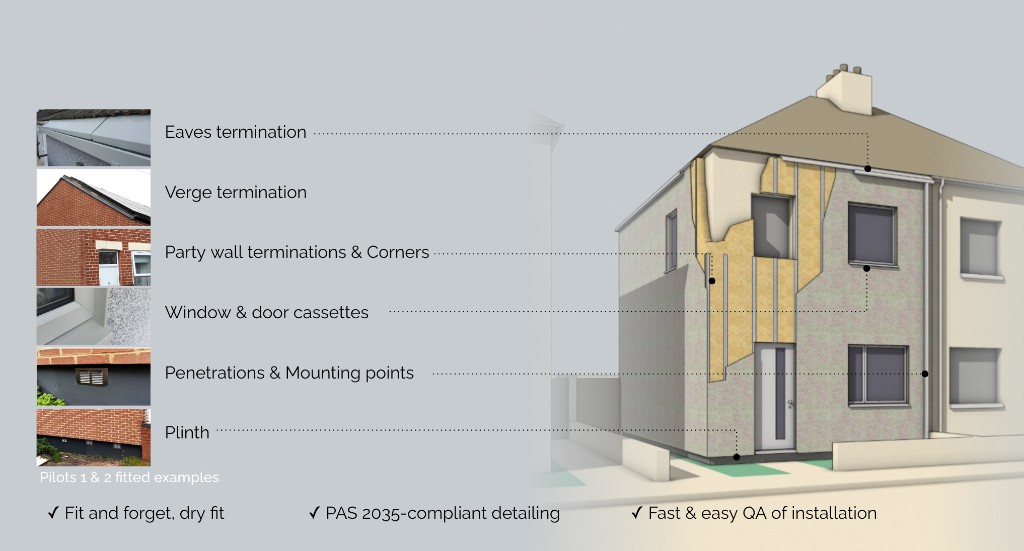

As well as our wall-panels, we've solved all the surrounding details, to provide a full system that's fast and easy to install.

5x faster than conventional EWI. Dry-fit means no weather delays and no wet trades on your programme.

Factory manufacture gives you certainty on time, cost, and quality. No reliance on individual skill.

Everything arrives on one lorry. One supplier, one programme, fewer interfaces. Learn more

A1/A2 fire-rated. No mortar to crack. No acrylic to degrade. No repainting. The last facade you'll ever need.

Precision-manufactured means nothing rejected on site. Helps you hit sustainability targets and the Future Homes Standard.

No specialist trades required. One person can pick it up and fix it. No crane, no telehandler, no lifting gear.

New Build

The average bricklayer is in their mid-fifties. It takes years to train new ones. Meanwhile, brick material costs have risen 39% since pre-pandemic, and ~10% of every order still ends up as waste. These panels give you a better-looking finish - without a single bricklayer on your programme.

We'll put together a feasibility assessment - no commitment.

Retrofit

It's slow, weather-dependent, and the rendered finish upsets residents and planners alike. At portfolio scale, every one of these problems compounds.

We'll put together a feasibility assessment - no commitment.

Real-World Proof

Installed with our first-generation system. Current panels deliver an even more realistic brick finish.

"From start to finish, the process was seamless, and the team was incredibly professional."

"The final result not only looks amazing, but has also noticeably improved the comfort and energy efficiency of our home."

Mahara Haque

Founder & Director, My Landlord Cares Property Management

How It Works

For new build, we work from your BIM models or plot drawings. For retrofit, we 3D-scan the existing building. Either way, panels arrive ready to fix.

3D scan (retrofit) or BIM models (new build) specify exact panel layouts and detailing

Panels manufactured to specification in controlled factory conditions

Everything arrives as a complete kit-in-a-box, on your schedule, plot by plot or property by property. See what's in the kit

Mechanically fixed by general operatives. No specialist trades required

Climate Incubator

Climate Incubator

Innovate UK

Innovate UK

Cranfield University

Cranfield University

TransformER

TransformER

No pitch. No pressure. Just a conversation about whether this makes sense for what you're building.

Let's have a conversationAdam Slader

adam@vundahaus.comAlex Whitcroft

alex@vundahaus.com